Can a Dutch company, Green Vinyl Records, without using natural gas, reduce the environmental impact associated with vinyl manufacturing?

At what point should artists and labels take ownership over the energy lost during the vinyl manufacturing process?

Traditionally, vinyl records are produced with a steam press. This can be time-consuming and expensive. Furthermore, the manufacturing materials within vinyl records contain a number of harmful ingredients, in particular during the recycling process. According to Greenpeace, PVC, the main ingredient of vinyl is the ‘most harmful of all the plastics.

So can Green Vinyl Records help change things? Their process removes PVC and natural gas from the equation which in turn can speed up production whilst helping the environment. The proposal can also go some way to solving the massive vinyl backlog. For label owners and artists alike, it’s an enticing proposition. We spoke to Harm Theunisse, the owner, to find out more.

Attack: Can you tell me a bit about your background and how you ended up rethinking vinyl manufacturing?

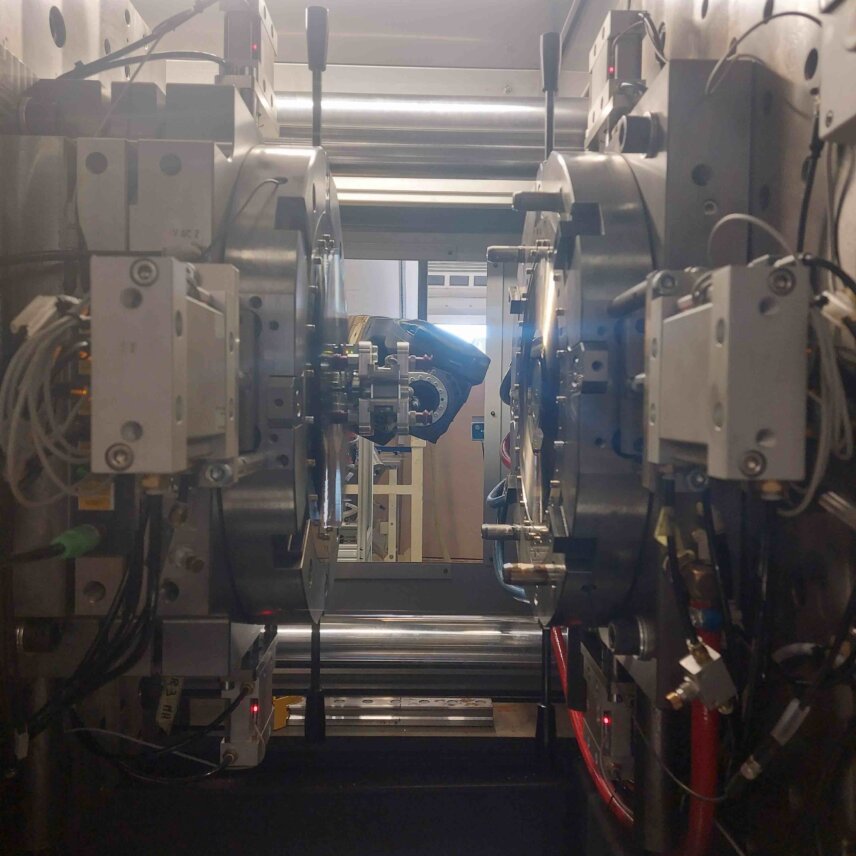

At school, I was always a technician and after school, I became an engineer at EMI in Holland. I was working on the equipment and at the time we were one of the biggest around. We worked for several brands and start to sell our own parts, machinery and later also chemicals that were used in the CD industry with our company Symcon.

In July 1997 Toolex Alpha and ODME announced the takeover of the larger ODME by the smaller Toolex Alpha. The fact that ODME, at roughly $150 million in revenues, was twice as large as Toolex Alpha raised a few eyebrows. After the takeover, I started freelancing for them.

At that point, I was travelling everywhere. Over my career, I’ve been to over 80 countries installing manufacturing equipment for vinyl, CD & DVD. I’ve basically been in software and hardware all my life. I’ve worked with every format from vinyl to CDs to DVDs for multiple sectors, not just music. I’ve worked in movies, software etc. If it had discs, I worked in it.

Really interesting. A good story as well. You mentioned in a recent interview that you’ve arrived with your new method and that it’s using up to 90% less energy. Are you able to elaborate on where those energy savings are being made?

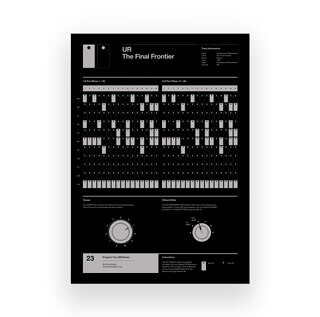

I measure the electricity of the whole machine, including the water-cooling water, the vacuum, the air compressor, the dryer – everything we measure. We only use electricity, and we analyze the data accurately.

It’s more common for a boiler to work with natural gas but it’s too slow and you need a lot of power to operate it. Using electricity, the way we do, the machine stays stable and we can therefore accurately monitor performance.

Was Green Vinyl Records born in response to a surge in demand for vinyl? Or was it something where you wanted to solve supply chain issues? Or perhaps an innate commitment to sustainability more generally?

It was a business decision, to be honest. I got bills and employees to pay and kids to look after. This seemed like a great opportunity that I’m excited to be a part of.

I’ve always solved problems in manufacturing and could see the potential to reinterpret and reinvent vinyl manufacturing.

With the ongoing war between Ukraine and Russia, having an energy-saving process like ours has never been more important. And as result, there is an environmental benefit.

There have been enquiries from all the major labels. We can help them of course to do larger runs, quicker and solve supply chain issues currently around vinyl manufacturing

How does your process affect the sound? A lot of dance music producers are rightly particular about bass response and there is a concern it might not have an efficient bass response. What would you say to someone who might be apprehensive?

It’s always going to be subjective. It also depends on I guess how much they know what they’re talking about technically!

My stampers and negatives are the same as what they would expect. The same is true for the master tapes.

Having said that, a lot depends on the quality of the tape received. Not all tapes received are correctly mastered for vinyl manufacturing and they are not sufficient to allow for the way frequencies shrink in production.

With CDs, there is very little fluctuation in tolerances and we’re reverse engineering CD quality to vinyl processing. Our product is as good if not better than anything else on the market. It’s the new standard.

What’s the ratio of your customers between small and big labels?

Right now it’s mostly smaller or underground labels.

But there have been enquiries from all the major labels. We can help them of course to do larger runs, quicker and solve supply chain issues currently around vinyl manufacturing.

It’s our belief that we are producing a new standard using no natural gas and without using PVC (polyvinyl chloride – which gave vinyl its name) which is attractive to any label size from various angles. Our system uses polyethylene terephthalate (Pet) – a more durable plastic which is easier to recycle. We only use electricity.

With the smaller labels, they typically require smaller runs. Are you able to do 50, 250 and 500 unit runs? Is there a minimum order quantity?

I can do whatever is requested. But the cost of a cut will always stay the same because producing a stamper is always the same process regardless of unit numbers.

Is using your service, at the moment at least, slightly more expensive?

They are the same prices as a PVC record. The cost price is actually cheaper. In the future, the price can also be reduced when processes are refined further. Are actual cost price is lower than PVC but our sales price is the same.

We find that price always challenges people’s commitment to sustainability. People tend to be less interested that we don’t for example use nickel once it hits them in the pocket.

I strongly believe this is going to be the new standard. There’s going to be a lot more research too and that will eventually bring down the cost. I’m optimistic about that.

We find that price always challenges people’s commitment to sustainability. People tend to be less interested that we don’t for example use nickel once it hits them in the pocket..

Do you see yourself solving the vinyl manufacturing supply chain issue?

Yes most definitely. It also requires a major label to step in but that is coming. They do have a global responsibility to lead the way alongside companies like our own.

What’s your opinion on this vinyl resurgence? Do you think it will last? Surely yes with what you’re doing...

Ultimately yes. With COVID, the war and rising prices, I think people are staying in more, partying more at home and using vinyl for that. You can pay $30 and you have it for life. There is a growing attractiveness about that as subscription services are broadly rental only. For every negative, there’s something positive. I’m confident in the growth over the next couple of years.

How quickly can you make 50 copies of a record?

It depends on the colour, but typically about one hour. There are of course variables but yes we can produce within an hour.

Do you offer a test pressing for labels?

Yes. It’s exactly the same as you would expect.

Who tends to ask about sustainability? The labels or the artists?

It’s not often artists mention it. They are more concerned with sound. They also want shrink-wrapped, recycled paper and so on but often forget about the disk.

Which artists are using you?

Tom Odell, David Vermeulen from Voltage and Richard Marx. For now!

We’ve also opened in the US so we anticipate a large swathe of artists and labels using us over there. There was a significant surge for example after the recent BBC Click feature.

Are there any ideas to team up with a company like Bandcamp?

Yes, it occurred to me that a collaboration with a company like Bandcamp could be a good way to pick up individual artists rather than labels. People can always contact us and our customer service is here to help.

What about competition in the market?

Like any sector there is competition, but their process is not like ours. We’ve refined it far more and removing natural gas from the equation is a huge difference. That’s what separates us from any competition.

Last question for you, are you a musician?

No, no! I just love making stuff work and improving processes. I always want to improve things, but I’ll leave the music to the artists! I’ll stick to the technical side!

Find out more about Green Vinyl Records. Find them on Instagram.