There’s a narrative that Eurorack is wallet-gougingly expensive but is this justified? We spoke with Noise Engineering and other manufacturers to understand the costs involved.

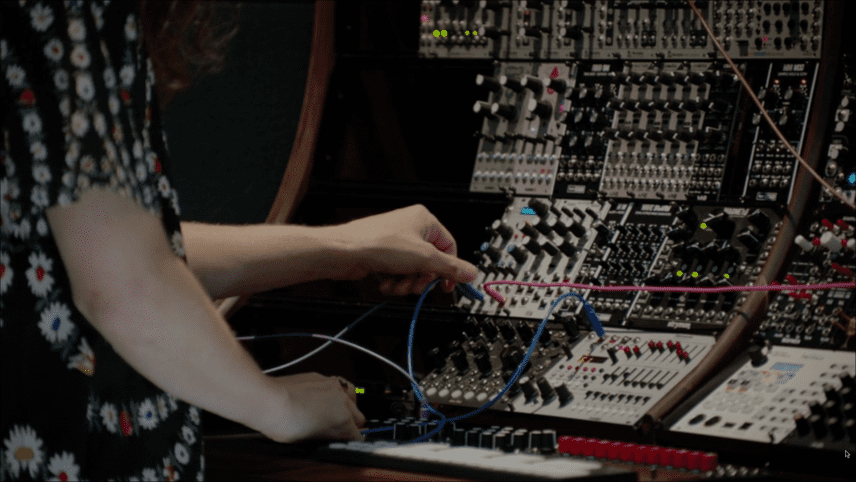

You’ve probably seen the memes, like “Eurorack – not even once.” They paint a picture of modular being prohibitively expensive. Even among the greater world of synthesizers – which isn’t exactly known for being affordable – Eurorack is seen as a money suck. And, if the marketing of a specific, large company is to be believed, elitist and bougie.

How true is this though?

Is Eurorack Expensive?

“I don’t think Eurorack is expensive,” retorts Robin Molten, journalist and head of Molten Modular, when we ask him about this. “To call something expensive implies that it’s overpriced or has some kind of premium value, where cheaper alternatives are just as good. I don’t think that’s the case.”

Robin’s view is probably shared by most hardcore Eurorack enthusiasts. It’s the perceived value held by non-users that may be the issue.

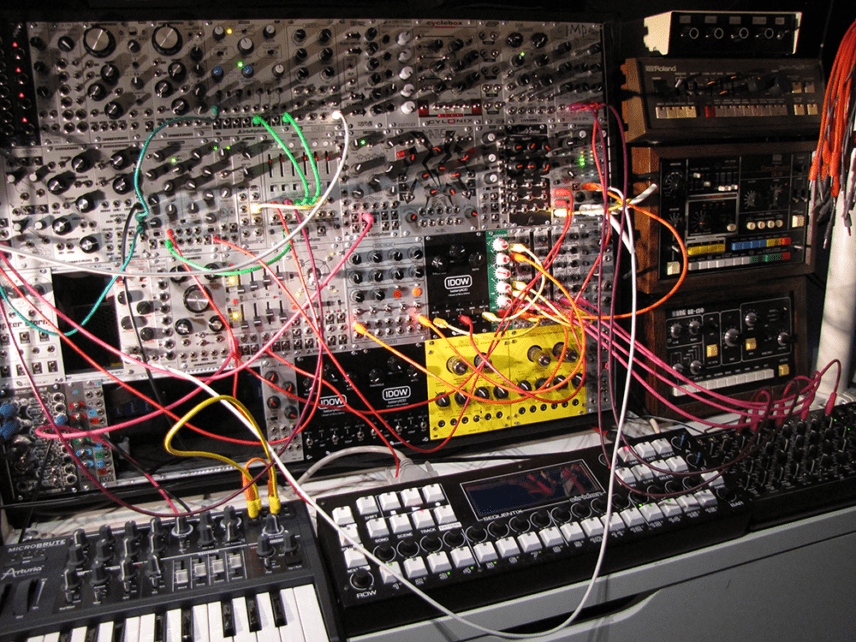

“Most people who have bought our products understand the cost,” explain Kris Kaiser, Doer Of Many Things, and Markus Cancilla, Chief of Destruction, at popular Eurorack company Noise Engineering. “I think more often, it’s people who are not customers who undervalue products. But the leap into Eurorack is a big one, and I can’t fault people for looking at that investment and balking. Most individual modules are not that expensive, but once you put a system together, it adds up.”

Something else to keep in mind is that Eurorack itself was designed as an affordable alternative to large Moog, Serge and Buchla modular systems, which can get very expensive indeed. So in that respect, Eurorack is actually cheaper than modular traditionally has been. And, by taking advantage of new manufacturing processes like miniaturization and overseas PCB fabrication, modular synthesis has ended up in the hands of many more people than it would have 20 years ago. “And that’s great,” says Robin, “but we have to accept that very real costs are involved.”

The Modular Side Of The Story

There is a lot that goes into the making of a Eurorack module, from design to manufacturing to promotion. From the get-go, though, you’re looking at a higher price point per unit than a full synthesizer or other instrument just because each unit requires separate manufacturing.

“It’s undoubtedly objectively true that the cost of building a modular system is greater than the cost of buying a hardware synthesizer of similar features,” explains Robin. “But that’s evident in the nature of the format. The cost of building two pieces of hardware, with individual PCBs, panels, connectors, software and functions, will inevitably cost more than making a single piece of hardware that incorporates both functions.”

Behringer reported that they had taken 50,000 preorders on the Pro-800. Instruo will probably sell a few hundred of the filter. The difference in cost between buying tens of thousands of components and buying a handful is huge.

Making a Module: Development Time Is Expensive

To get an idea of how a module is made – and thus the expenses that build up at each stage – we asked Kris and Markus at Noise Engineering to walk us through the process of making a module.

1. Meeting

“We have regular all-hands design meetings where anyone can bring ideas. The average concept has about 15 person-hours of discussion before we start schematic capture. Schematic and PCB design are generally reasonably fast in most cases. We argue the layout once more and order the prototype. Our contract manufacturer builds our prototypes so we can usually work out issues and part availability before we get to production. Prototypes are relatively expensive per unit so we spend a lot of time up front to minimize the revisions, though most products will have a couple of versions.”

2. Firmware

“Once we have hardware in hand, we write the custom firmware for the product. In the beginning, this is generally Markus and Stephen (McCaul) arguing over behaviors and knobfeels, but when we are closer to production, we bring the whole team in. I estimate we have hundreds of person-hours of test and development on the average product. The module then goes to production.”

3. Releasing The Module

“There are also the costs involved with releasing the module: we do all of our video production in-house, and we also create our own documentation, advertising copy, product pages and supporting information. Once the product ships, we also answer every customer email we receive.

“We are small but everyone here makes a living wage and gets paid benefits, so development time is expensive.”

The Hidden Cost of Manpower

When the customer buys a module, if they think about the price at all they’re probably thinking in terms of the physical aspects of the unit: the housing, knobs and sliders, and components. But there’s another cost that doesn’t often get considered by the consumer: the cost of manpower.

“Currently, Noise Engineering is composed of seven passionate and nerdy folks, and everyone is involved in some way in the design of all of our products,” stress Kris and Markus. “Most of our designs are a bit more on the complex side … and all of that adds up to months or even years of work. From start of concept to product launch, I’d guess most of our products tally over a thousand person-hours easily.”

The Manufacturing Side Of The Story

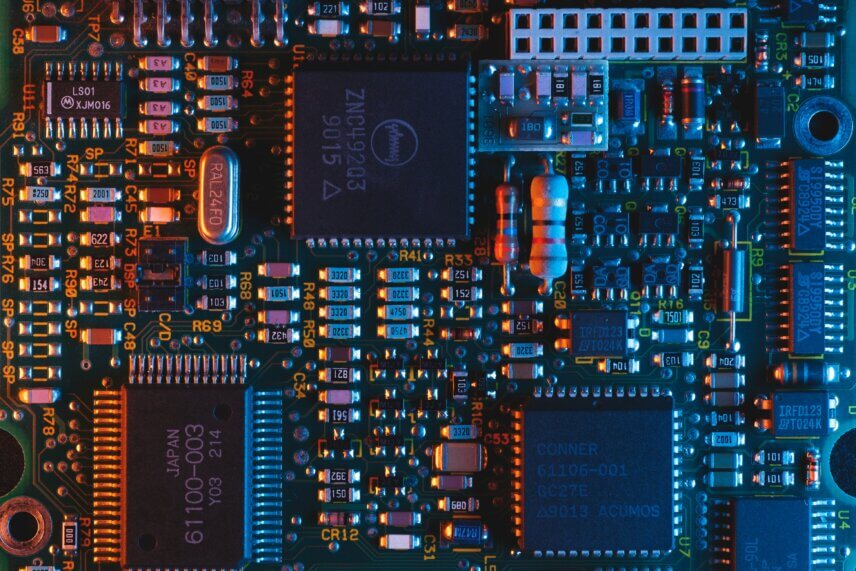

While some Eurorack companies will hand-make their modules in-house, it’s much more common to send them out to be manufactured. This is when the company partners with a manufacturing outfit like Electro-Distro, which specializes in turnkey manufacturing for boutique audio companies. They can handle the entire manufacturing process from parts procurement and SMT assembly, all the way to quality control, mechanical assembly, and final packaging.

Module Cost Breakdown

“Many customers think that the cost of a Eurorack module is simply the cost of materials and markup and consequently assume that many modules are exorbitantly overpriced,” explains Andrew Ikenberry of Electro-Distro and Qu-Bit Electronix. “The fact of the matter is that the cost of the parts actually represents one of the smaller pieces of the retail price pie.”

According to Andrew, the overall costs associated with a module break down as follows:

- Materials cost

- Manufacturing labor

- Distribution cost labor

- Net profit margin

- Dealer profit margin

It’s clear that there are many stages in the manufacturing process that cost money and all of these contribute to the overall price.

An important concept to keep in mind when comparing the price of a Eurorack module to other instruments is that of economies of scale.

Economies Of Scale

An important concept to keep in mind when comparing the price of a Eurorack module to other instruments is that of economies of scale. Essentially, the more of a unit that you manufacture, the less each unit costs to build. It’s similar to buying bulk from Costco versus a single item at a grocery store. The individual cost of a bottle of water, for example, is less when you buy 24 of them in a bundle versus just one at a time.

“What people often don’t realize is that larger brands benefit from an economy of scale that small, boutique brands do not,” say Kris and Markus. “As a concrete example, we’ve only manufactured a few hundred of some of our utility modules. Companies like Apple build millions of units. Every single part that goes into a product is cheaper when you manufacture at the scale of Apple. That brings the cost down enormously but also requires the ability to purchase the raw materials in advance, something that only very large companies can really do.”

Robin Molten gives another concrete example: “Take a quick comparison between Behringer and modular manufacturer Instruo. Behringer has just released the Pro-800 polyphonic analog synthesizer that you can buy for £345. Instruo has just released the Aradh Transistor Ladder Filter and VCA for £329. The Pro-800 contains eight of those filters and VCAs; how can they be comparable in price? Well, because there’s nothing about those two companies that’s the same. Behringer reported that they had taken 50,000 preorders on the Pro-800. Instruo will probably sell a few hundred of the filter. The difference in cost between buying tens of thousands of components and buying a handful is huge.”

Robin puts it another way: “Instruo are not overcharging for their modules; they are charging what they need to charge to cover the cost of the unit and the cost of running a decent business.”

The Retail Side Of The Story

So far we’ve looked at the costs associated with the design and manufacturing of Eurorack modules but there’s one that we haven’t mentioned yet: retail. Stores, whether they be brick-and-mortar or online, will take their cut, as will distributors.

“It is important to remember that if you bought a module through a retailer,” says Andrew of Electro-Distro, “the store had to make a profit themselves in addition to what the module designer needs to make in order to stay in business.”

Molten Modular offers a few utility modules and Robin’s experience with this is eye-opening. Explains Robin: “The Molten Motion Meter (made in collaboration with Befaco) is a relatively simple analog module and costs £130 to buy from a shop. Take off VAT and you have £104. A shop needs about a 30% markup on every product in order to exist – it doesn’t matter what the product is. So the module is sold to the shop at about £75. Before you even look at the cost of making the module, almost half the price you pay supports the system by which you are able to purchase the module.”

What Does Too Expensive Mean?

A large Eurorack rig may be more expensive than a similarly sized single synthesizer or drum machine but then again what you’re paying for isn’t just a handful of components and knobs but the thousands of person-hours of work that have gone into designing, testing and selling the units. Not to mention the very real costs that have accrued along the way.

“It’s easy to forget that there are people behind the products,” say Noise Engineering’s Kris and Markus. “We’re a small team of seven passionate people, each working every day to make the products the best they can possibly be. We each have an integral role in everything we make. Everyone deserves to be paid a living wage, and to be treated fairly, and that costs money, but it’s the right thing to do.”

More than this even, Eurorack is a special scene. Many of the most ground-breaking advancements in synthesis in the last 10 years have come from Eurorack and its willingness to experiment. These are not mass-market products and so can never be as cheap as something made on a large scale.

“If we want innovative, interesting, diverse and meaningful modules then we need to enable the small manufacturers to pay their bills, pay their staff and make a living,” stresses Robin Molten. “The passion that is unlocked in the understanding that we are happy to pay for someone to build a business making modules full time can’t be undervalued.”

So, is Eurorack expensive? “No,” restates Robin. “It requires an investment that’s appropriate to the business of making these extraordinarily creative machines. The freedom, fun and creativity that this format has ignited in me is absolutely worth every penny.”

01.06 PM

And all these suppositions are turned upside-down by Behringer. The truth is the quality of the Eurorack is not determined by manufacturer or price but by the user. How many times have we wondered how So and So got that “amazing sound” and found out it was something creative with minimal tools or just stock plugins. The greatest musical tool ever built is our brain. Joe

07.45 PM

um no Behringer leapfrogs over the entire R/D, engineering, and design process by reverse-engineering popular products, then uses an already in-place manufacturing/logistics pipeline (previously only dedicated to cheap knockoff pro audio gear) to crank out stolen IP to flood the market with.

05.51 AM

Such an original comment drip droodle. Dont you have a yt video to make of your eurorack system playing drones surrounded by potplants?